Summary:

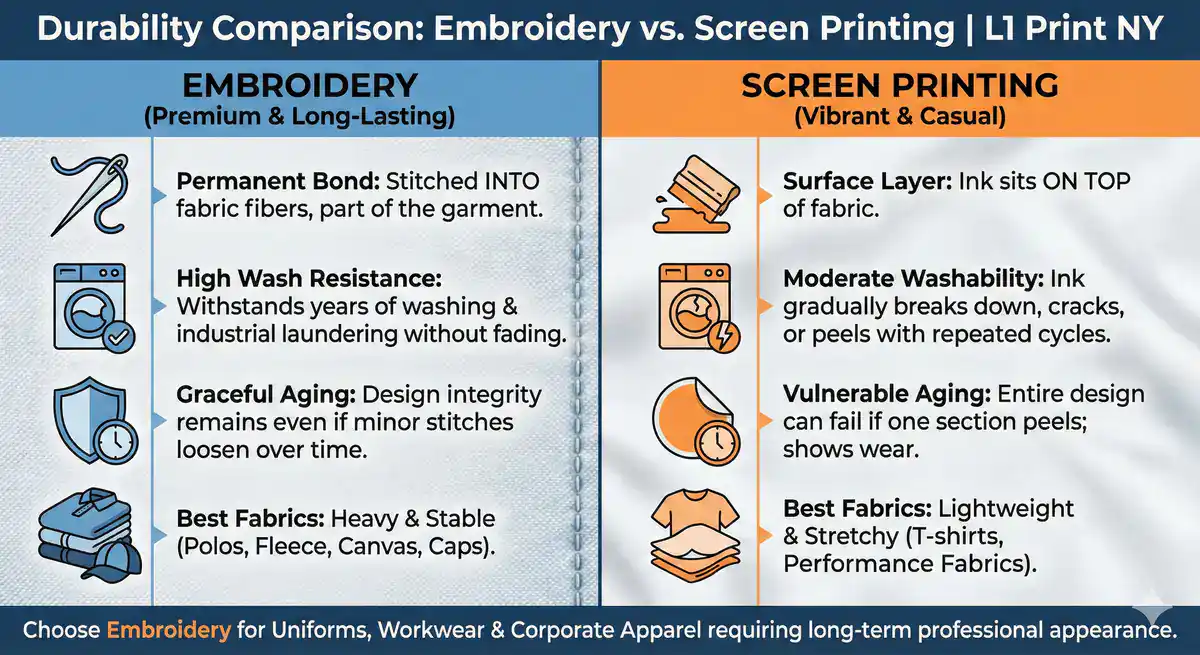

Embroidery creates a permanent bond with your garment that screen printing simply can’t match. The threads are stitched directly into the fabric fibers, becoming part of the garment itself rather than sitting on top like ink.

This fundamental difference means embroidered logos withstand years of regular washing, daily wear, and even industrial laundering without fading, cracking, or peeling. Screen printed designs, while initially vibrant, can show wear over time as the ink gradually breaks down with repeated washing cycles.

When you’re investing in uniforms, corporate apparel Long Island, or any item that needs to maintain its professional appearance through heavy use, embroidery’s longevity becomes a cost-effective choice despite the higher upfront investment.

The secret to embroidery’s durability lies in how the threads integrate with your garment’s fabric structure. Each stitch penetrates multiple fabric layers, creating thousands of anchor points that distribute stress across the entire design area.

Modern embroidery threads are engineered for performance. Rayon threads provide that premium silky sheen you see on high-end corporate apparel, while polyester threads offer maximum durability for workwear and uniforms that face tough conditions. The thread choice depends on your specific application, but both options far outlast screen printing inks.

This construction method explains why embroidered designs maintain their dimensional appearance and color vibrancy even after hundreds of wash cycles. The threads don’t just sit on the surface where they’re vulnerable to abrasion and chemical breakdown from detergents.

Unlike screen printing where the entire design can fail if one section starts peeling, embroidered designs degrade gradually and gracefully. Even if a few stitches come loose over years of use, the overall design integrity remains intact.

The digitizing process that converts your logo into stitch patterns also optimizes thread paths for maximum durability. Professional digitizers understand how different stitch types, densities, and directions affect longevity, ensuring your design is built to last from the ground up.

Embroidery performs best on thicker, more stable fabrics that can support the stitching without puckering or distorting. Polo shirts, fleece jackets, canvas workwear, and structured caps provide the ideal foundation for embroidered logos that will maintain their shape and appearance over time.

Cotton blends, particularly those with some polyester content, offer the perfect balance of stability and comfort. The cotton provides a natural feel while the polyester adds dimensional stability that prevents the fabric from stretching or shrinking around the embroidered design.

Avoid embroidery on very lightweight t-shirts, stretchy performance fabrics, or loosely woven materials. These fabrics don’t provide adequate support for the stitching, leading to puckering, distortion, or premature wear. Screen printing works better on these lighter materials.

The fabric weight and weave also affect how your logo will look. Denser fabrics showcase embroidery’s dimensional quality, making logos appear more substantial and premium. This is why you see embroidery on executive polo shirts, outerwear, and other garments where a polished, professional appearance matters most.

Consider the garment’s intended use as well. Workwear that faces abrasion, frequent washing, or harsh conditions benefits from embroidery on heavy cotton duck, canvas, or ripstop fabrics. These materials can handle both the embroidery process and the demanding work environment without compromising the design quality.

Want live answers?

Connect with a L1 Print expert for fast, friendly support.

Embroidery creates a premium, three-dimensional appearance that instantly elevates any garment’s perceived value. The raised texture and subtle sheen of embroidered logos convey quality and attention to detail in ways that flat screen printing cannot match.

This dimensional quality makes embroidery Long Island the preferred choice for corporate environments, client-facing roles, and any situation where your apparel needs to project professionalism and success. The tactile element adds perceived value that customers and colleagues notice, even subconsciously.

Screen printing, while capable of vibrant colors and detailed designs, creates a flat surface that can appear more casual or promotional in nature.

Executive polo shirts, dress shirts, and blazers benefit tremendously from embroidered logos. The sophisticated appearance aligns with professional dress codes while ensuring your brand representation maintains its quality through regular business use.

Embroidery works particularly well for left chest logo placement, the most common position for corporate apparel. The smaller size requirements play to embroidery’s strengths while creating that classic, professional look associated with quality business attire.

Consider how your team will be perceived by clients, customers, and business partners. Embroidered logos on quality garments send a message about your company’s attention to detail and commitment to quality. This matters in industries like finance, healthcare, consulting, and other professional services where image directly impacts business success.

The durability factor becomes even more important in corporate settings. Professional uniforms need to maintain their appearance through frequent wear and cleaning. Embroidered designs ensure your team looks polished and professional every day, not just when the garments are new.

Restaurant and hospitality uniforms also benefit from embroidery’s durability and professional appearance. Kitchen environments, frequent laundering, and constant customer interaction demand decoration methods that maintain their quality under demanding conditions.

Baseball caps, beanies, and other headwear showcase embroidery’s advantages perfectly. The curved surfaces and varied fabric textures of hats make screen printing difficult or impossible, while embroidery adapts to these three-dimensional shapes naturally.

Embroidered hat logos maintain their appearance through sun exposure, rain, sweat, and regular handling that would quickly degrade screen printed designs. The thread construction handles the flexing and stretching that occurs with normal hat wear.

Jackets, fleece, and outerwear present similar advantages for embroidery. These garments typically use heavier fabrics that support embroidery well, and they’re often worn in conditions where durability becomes crucial. Weather resistance, abrasion from backpacks or equipment, and frequent washing all favor embroidered decoration.

Bags, backpacks, and promotional items made from canvas, nylon, or other heavy materials also work well with embroidery. The decoration becomes part of the item rather than an applied surface treatment, ensuring it survives the handling and use these items typically receive.

The key advantage here is longevity. These structured items often represent a significant investment, and you want the decoration to last as long as the item itself. Embroidery delivers that longevity while maintaining the professional appearance that reflects well on your brand.

The decision between embroidery and screen printing ultimately comes down to your specific needs, timeline, and how you want your brand represented. Embroidery excels when durability, professionalism, and premium appearance matter most.

Choose embroidery for corporate polos, structured hats, outerwear, and any application where the garment needs to maintain its professional appearance through heavy use. The higher upfront cost becomes a smart investment when you factor in the extended lifespan and consistent brand representation.

Screen printing remains the better choice for large designs, complex graphics, lightweight t-shirts, and situations where vibrant colors and detailed artwork are priorities. Understanding these differences helps you make informed decisions that serve your brand well.

For the best results, work with us at L1 Print where we handle both embroidery and screen printing in-house, ensuring perfect color matching and consistent quality across your entire order.

Continue learning: